Add:3th floor, building 5, xinhe

road,Hebei town,Baitian,

Longgang district,Shenzhen

Tel:0755-029021712

Mob:13802269377

13510750303

Ser:13826528967

Fax:0755-22143047

Email:smt@szdfk.com

Web:www.szdfk.com

PRODUCTS

Product description :

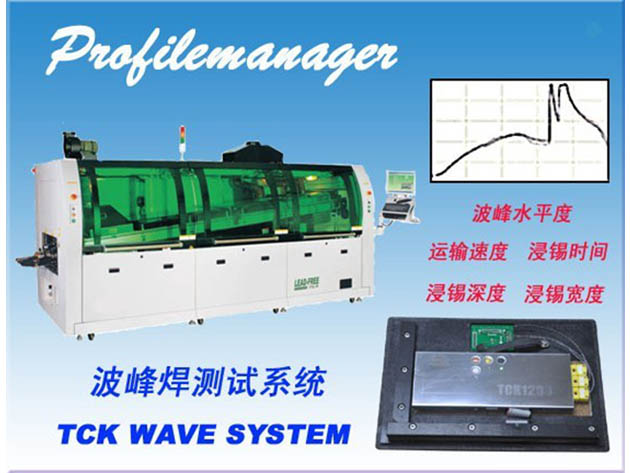

TCK-1206 test system is the wave soldering soldering temperature test system designed for professional users DIP by the TCK series thermometer and W-1 wave soldering test frame composition, in addition to the test temperature curve , the increase in the peak level of the test , depth of immersion tin , tin wave height, speed of transportation , immersion tin and immersion tin time width . 2012 TOPCITY technical staff through the test fixture W-1 improved functionality makes testing more powerful, easier to use and is ideal for wave soldering temperature testing.

The main technical indicators:

1 , model specifications : TCK1203/06/09/00

2 , the test channel : 3/6/9/12 CH

3 , Thermocouple : K type

4 , temperature range : 0 --- 1000 ℃

5, the temperature measurement accuracy : ± 1.2 ℃

6 Resolution : 0.1 ℃ ( full scale )

7 , recorded data: 80000 points / per channel

8 , the sampling interval : 0.25 ---- 600 seconds the software settings

9 , Total power : ≤ 100mW

10 , operating voltage : 3.6VDC ( built-in rechargeable battery )

11 , Dimension : 196 (L) × 103 (W) × 21 (H) mm

12 protection box size : 250 (L) × 133 (W) × 30 (H) mm

13 , the test frame size : 268 (W) × 296 (L) mm

14 , wingspan : 145 ------ 268mm ( standard )

15 , communication ports : RS-232 or USB / RF

16 , analysis software : ProfileManager V1.50

Instrument configuration :

1, the temperature analyzer 2 , instrument protection box 3 , 4 thermocouple , software installation disk 5, the data output lines

6 , high temperature adhesive tape 7 , 8 charger , equipment boxes 9 , 10 scissors , tweezers

11 , insulated gloves 12 , 13 Phillips screwdriver , high-temperature solder wire 14 , 15 user manual , product certification

16 , the antenna ( optional ) 17 , high sensitivity antenna ( optional ) 18 , a wireless transceiver ( optional )

Set the temperature curve analysis function ( data analysis ) :

1 , the peak reflow oven and set the oven temperature and the transport speed zone

2 , the temperature of the sample point location name and PCB schematic

Time 3, between any two temperatures

4 , the slope between any two temperatures

5 , the slope between any two time points

6 , the temperature exceeds the specified time

7, the highest temperature and the temperature at any point in time

Time 8 , horizontal temperature line, vertical line and the time between two time

9 , mesh refinement and editing curves zoom display

10 , the analog curve function , process optimization, test date and time

11 , enter the company name, product name , and notes information

12 , select the print direction (horizontal and vertical print print )

13 , reports temperature data can be exported to Excel for editing

14 , insert the image, so that the temperature test point locations at a glance

15 , calling multiple temperature curve comparison

16 , real-time monitoring and recording equipment are two operating modes

17 , clear instrumentation and software manually clear the way memory data

18 , Manual, specified time, a specified temperature three starts

19 , the product database management

20 , Device Database Management

21 , Paste Database Management

22, PWI technology index analysis

Wave soldering proprietary test function :

1 , the peak level of the functional test

2, the test immersion depth features

3, the test solder wave height function

4 , test equipment chain speed function

5 , immersion tin time function test

6 , immersion tin width function test

7 , the slope of the function test preheating zone

8, the test function of the maximum temperature of the preheating zone