Add:3th floor, building 5, xinhe

road,Hebei town,Baitian,

Longgang district,Shenzhen

Tel:0755-029021712

Mob:13802269377

13510750303

Ser:13826528967

Fax:0755-22143047

Email:smt@szdfk.com

Web:www.szdfk.com

PRODUCTS

Product introduction:

As theSMT PCBAIn the assembly of components is more and more small, component assembly density is more and more big, the solder joint is becoming more and more small.Defects in welded on the circuit board has70%Actually came from the solder paste printing process control is not good enough.Solder paste thickness machine can be found in the printing process effectively potential adverse, provide effectiveSPCProcess control data, make the bad is greatly reduced.Combined with the current electronic manufacturing competition, the more defects means the loss of profits, and even lead to losses.A growing number of companies in the issuance of electronic manufacturing foundries, more and more strict with the quality process control, usually require contract have the equipment, have the ability to control the solder paste printing process.

Function introduction

1. The thickness, length, distance, area, volume, diameter, the Angle measurement

Numerical list, 2. The height can be set up project files, permanent data storage, look over a certain period of time at any time of the SPC

3. The thickness control analysis

4. The thickness of the numerical multipoint and single point analysis

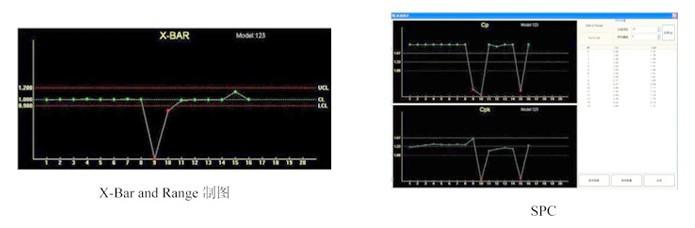

5. Provide X - Bar, Range, CP and CPK control charts

6. Data and save the analysis diagram output, provide text and Excel format

7. Center distance measurement, the center of the circle to the straight line distance.

8. Provide a lower limit on the maximum and minimum control specifications set

9. High-definition color CCD320 pixel camera, precision of + / - 0.002 mm, can be easy to adapt to the minimum 01005 welding plate

Testing requirements;

10. Repeat the measurement precision can be within 0.005 mm control;

11. A high-precision laser brightness adjustment, in order to meet the special color and the needs of different customers;

Permanent 12. Measurement data, and can at any time to check the SPC fluctuations in a certain period of time, high traceability;

13. The operation is simple to understand, the new staff and skilled operation can be mastered within half an hour, for clients to solve the problem of employment is difficult;

14. The marble surface and high precision processing, high stability, not easy to deformation, which can keep the precision of demand;

15. Small volume, less occupying space;

16. Measuring speed, report timely and effective, accurate numerical (maintained through metrological testing technology research institute of Shanghai detection)

17. The software is so powerful that provide control on the floor and specifications on lower limit set, the quality control in the clear.

Technical parameters:

1.Measuring principle :Non-contact, laser line;

2.Accuracy of measurement: -0.002mm;

3. Repeated measurement accuracy:Or less0.005mm

4.Vision:10 mmX8 mm;

5.Camera:320M;

6.Auxiliary measures: / polygon areaLine length/Angle /Volume;

7.platforms: fixed marble platform;

8.Installation dimensions:420

mmX410mmX310mm;9.Optical magnification:50 times.

10.Measuring the light source :High precision laser red line;

11. The power supply: 220V, 60Hz;

12.System weight:about20Kg;

13.Lighting system:Adjustable brightness ringLEDThe light source ;

14. The computer configurationDell:The computer,19Inch widescreen display